Our broad range of animal solutions is designed to maximize ROI, enhance performance, and improve animal well-being.

We continuously adapt our production processes, product formulations, and technologies to meet our markets’ evolving needs and ensure optimal usability of our solutions.

OUR TITAN TECHNOLOGY:

Live microorganisms are not always naturally resistant to the feed manufacturing process and associated constraints. The probiotic’s objective is to remain “alive and active” from the manufacturing plant to the host’s digestive tract. Many parameters can interfere along the way to reduce the viability of the yeast cells. As a result, protection can be necessary for specific probiotics to ensure their stability through the feed pelletizing process and during storage.

TITAN is a specific technology that protects the live yeast against the constraints of feed production and ensures stability through storage. TITAN is unique. It is the result of optimizing fermentation, production, and drying processes. In addition, Lallemand adds a specific and patented coating technology to make this microencapsulated live yeast even more resistant.

Resistance to feed manufacturing

Numerous trials, both from independent institutes and commercial feed manufacturers, demonstrate the unique and consistent capacity of LEVUCELL TITAN to resist most of the pelleting conditions from standard to more drastic ones. Lallemand Animal Nutrition technical team can help you set up a validation plan according to your feed manufacturing conditions.

Stability over time

Stability is also about feed storage conditions and shelf life. Once probiotics are included in the feed, the products must survive storage at the feed mill or farm. TITAN technology allows yeasts to remain stable in the feed through the storage period.

Our products LEVUCELL SC and LEVUCELL SB are both available in TITAN technology.

LALLEMAND STABLE SUSPENSION TECHNOLOGY:

What is it?

Lallemand Stable Suspension is a proprietary technology designed specifically for the MAGNIVA forage inoculant range. This technology can be found in every sachet of MAGNIVA, and it ensures that — once mixed with water — the inoculant remains viable and in an even suspension throughout the harvesting process.

What are the benefits of this technology?

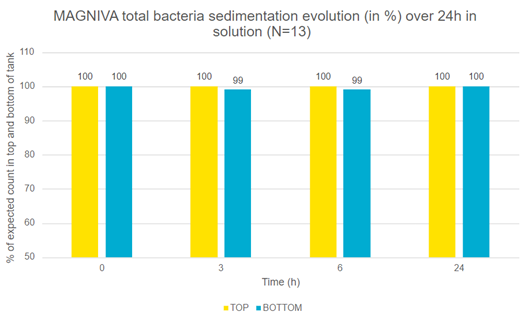

Bacterial concentrations in the applicator can vary enormously as the bacteria in traditional inoculants tend to rapidly settle once in solution. This leads to uneven application of the product across the forage being harvested. Lallemand Stable Suspension ensures that once mixed, MAGNIVA forage inoculants remain in an even suspension over 24 hours, meaning the product is always applied at the correct application rate. Reducing the likelihood of the product settling in the solution also means applicators are less likely to get blocked, which can slow down the harvesting process and increase costs.

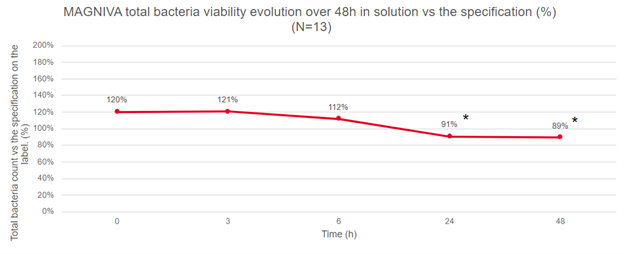

Lallemand Stable Suspension also improves bacteria viability once mixed. After 48 hours, MAGNIVA forage inoculants will still be at least 90% product specification, which is within the margin of error for the method used to count bacteria. Improved viability means contractors and producers can be more confident of the product’s efficacy if a breakdown or any other delay in harvesting occurs.

USING THE CORRECT INOCULANT IS CRUCIAL, ENSURING THE PROPER APPLICATION RATE IS EVEN MORE SO!

Quick overview of the benefits of LALLEMAND STABLE SUSPENSION:

- Improves bacterial suspension characteristics when mixed with water over 24 hours

- Consistent and accurate application of the inoculant to the forage

- Reduces settling in the applicator, which lowers the risk of sprayer clogs

- Better bacterial viability after 48 hours in suspension means contractors can be confident of product viability, even in the event of a breakdown

- Produces higher quality silage by ensuring an even application of the inoculant over forage

- Saves time by avoiding extra mixing

- Does not waste product and helps ensure inoculant efficacy in case of harvest delays