News | Reading Time 4 minutes

Focus on dry matter this silage season

In light of difficult weather conditions, focus on achieving between 28-33% dry matter (DM) when ensiling grass to favour good fermentation.

We’re expecting first cuts to be high in fibre and lignin and low in dry matter and sugars.

“Adding to this, increased thatch and wet ground conditions could increase the likelihood of contamination. All these factors will mean making quality silage will be a challenge this year.

“Grass has not had the best conditions to start the season. Many people have been unable to graze, top, roll or fertilise this spring. This combined with a lack of sunshine has limited normal spring grass growth.”

Achieve optimum dry matter before clamping

To help mitigate these problems, Mrs Colahan advises taking steps to achieve optimum dry matter, as this is the centrepiece to achieving good fermentation.

“Using a mower with a conditioner, tedding and also monitoring dry matter closely can all help get the grass dry before clamping.”

Alongside practical management techniques, an inoculant should also be used to help promote good fermentation and preserve what quality you have been able to achieve.

“The dual purpose of the bacteria and enzymes within the Magniva product range of crop- and condition-specific inoculants supports rapid and efficient fermentation.”

Enzymes important for low sugar grass

Enzymes are especially important when we have overcast conditions and low sugar grasses. Enzymes have the ability to unlock specific bonds in the fibre fraction to release additional sugars needed to fuel the initial fermentation.

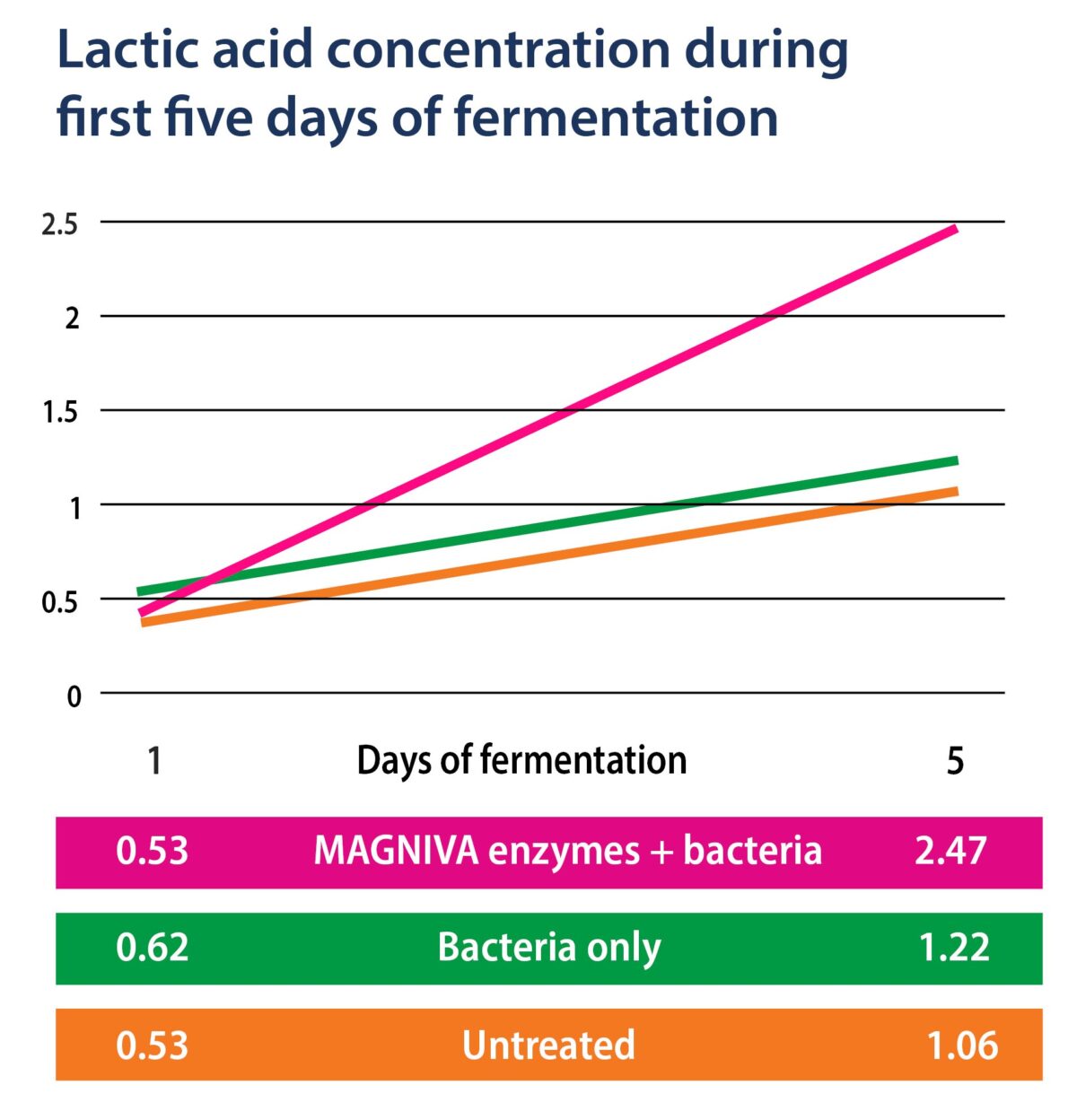

“A trial on low sugar grass looked at lactic acid concentration during the first five days of fermentation. It showed that when using Magniva, which contains enzymes and bacteria,1.25% more lactic acid was produced during this early period.

“Both the untreated grass and grass treated with only bacteria contained half the levels of lactic acid as the Magniva treated grass. This is because they could not access additional sugar to drive the lactic fermentation.

“The rapid lactic acid production encourages the pH to drop rapidly. This promotes quicker fermentation and better nutrient retention,” she says.

Wet grasses not stable without the right inoculant

Mrs Colahan adds that the historic thinking that wetter grasses will be stable during feed-out is no longer relevant. This is because the UK climate has changed in the last 40 years with warmer winters and higher average temperatures. These conditions make even wet grasses susceptible to yeast growth and poor aerobic instability, as we recently recorded in our research trial from the University of Reading.

“In the Reading trial comparing grass silage at 23-26% DM, the control clamp started to heat after 24 hours. By contrast, the treated silage gave over five days stability. Furthermore, temperatures in the control peaked at 34.6oC, whereas the treated silage reached only 26.7oC. This extra 8oC of heating in the control group is the equivalent of losing 28MJ of energy for every tonne of silage fresh weight that is unstable. This equates to 5.4kg of milk lost.” she says.

By combining homo- and heterofermentative bacteria with a specific enzyme formulation, we are ensuring you get a rapid and efficient fermentation followed by a stable, palatable silage during feed-out.

“Further research compared Magniva* treated silage with the control and showed that the digestibility of the treated silage was 19% higher than the control silage after eight hours. This again shows that cows can get more from the treated silage,” she says.

Published Apr 30, 2024 | Updated Aug 12, 2024

Related articles

Need specific information?

Talk to an expert