Blog | Reading Time 5 minutes

How to make the most of cereal crops

Following the unfavourable conditions faced this year, which could lower grass silage quality, cereals offer flexible options.

Three ways to use cereals

Cereals are versatile crops that can be used in three ways to bolster ruminant diets. Whether you are looking for a good source of fibre, a rumen-friendly starch, or a convenient concentrate feed, cereals offer a range of options to suit different feeding systems and nutritional needs.

Below we explore the many advantages of cereal crops and provide practical insights on different ways to integrate them into ruminant diets.

1. Wholecrop silage

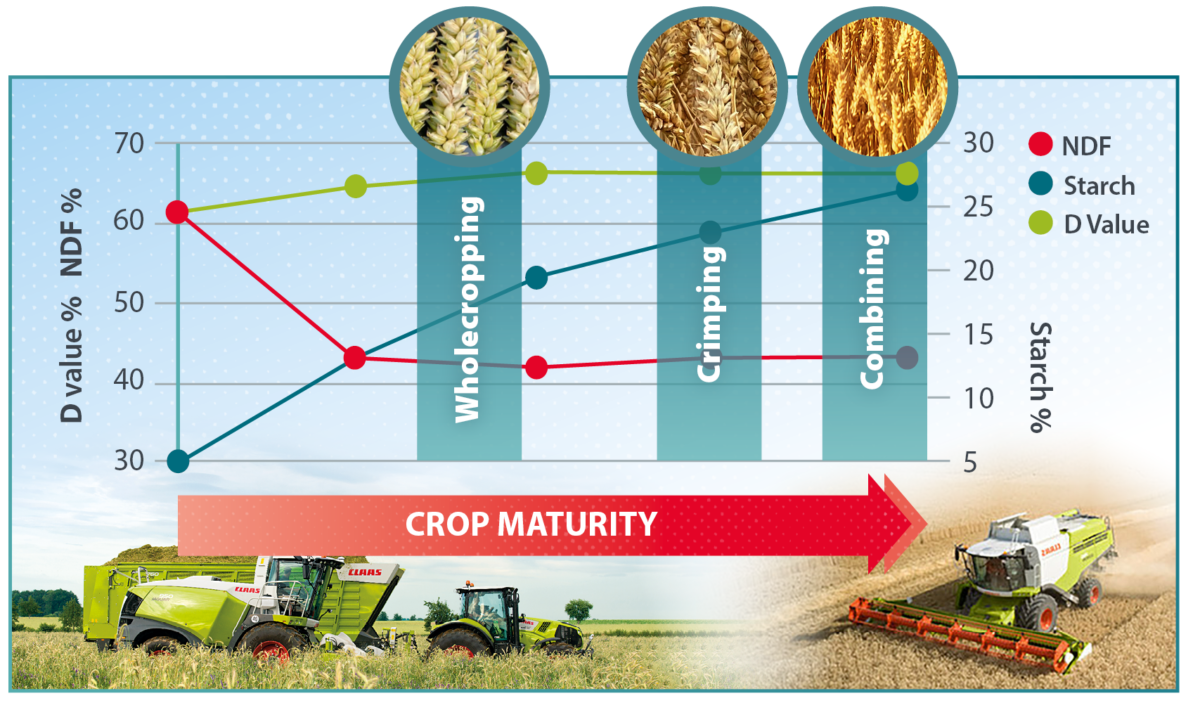

The entire cereal plant can be harvested and fed as silage, providing a feed option rich in fibre and starch. Wholecrop silage offers several benefits:

- Encourages rumination: Wholecrop silage includes the straw fraction, providing a less digestible fibre. This is essential for stimulating rumination and improving the overall function of the rumen

- Scratch factor: The fibre stimulates the walls of the rumen which encourages rumination and aids digestion

- Fibre and starch source: It complements highly digestible, early-cut grass silage well, balancing the feed by providing both fibre and starch

2. Crimped Grain

If wholecrop silage does not fit your system, crimping the grain is a great alternative use for cereals. When the grain reaches a ‘cheddar cheese’ consistency, it can be crimped to provide a starch source with lots of benefits, including:

- Rumen-friendly: Crimped grain has a less rapid impact on the pH of the rumen and is less likely to cause acidosis as it ferments differently to ground cereals

- Balancing rations: Crimped grain is a useful option if you have large amounts of grass silage that lacks quality leaving the diet short of energy

- Secondary product: If conditions allow, the straw left after crimping can be baled and used as bedding or feed

3. Combining cereals

The third option is to leave the crop to mature fully and combine it to produce a concentrate feed. The benefits of combined grain include:

- Easy management: Dried grain is easier to store and manage than crimped grain, making it a practical option for many farmers. It can also be sold on

- Secondary product: Combining the crop also produces straw, which can be used as feed or bedding

- Energy source: Dried grain offers a rapidly available energy source, which works well with rapidly available protein. However, it is important to note that if the diet is unbalanced, rapidly fermentable dried grain can cause acidosis

All three of these options offer different advantages, allowing you to choose the one most suited for your farm. By understanding and making the most of the versatility of cereals, you can enhance your feed strategy and improve the overall health and productivity of your livestock.

How to maximise the quality of cereals

Inoculants play a vital role in enhancing the fermentation process and preserving the nutritional value of both wholecrop silage and crimped grains. Here’s how to effectively use inoculants for each type of feed.

Using a crop- and condition-specific inoculant on wholecrop silage

Applying a crop -and condition-specific inoculant, such as Magniva Platinum Wholecrop, to wholecrop silage can significantly improve fermentation quality and feed stability.

This crop- and condition-specific inoculant contains enzymes and beneficial bacteria that break down the fibre bonds in the crop to release sugars and kickstart the fermentation process. This helps to reduce the pH more rapidly and helps to outcompete spoilage organisms.

Magniva Platinum Wholecrop contains heterofermentative bacteria which converts sugars into lactic acid, acetic acid and propionic acid among other by-products. These acids create an environment which optimises the fermentation and reduces the likelihood of silage spoiling when exposed to air by preventing the growth of yeasts and moulds.

Applying an inoculant to wholecrop silage is done during harvesting via the built in applicator in the harvester.

Using a crop- and condition-specific inoculant on crimped grains

For crimped grains, using a crop- and condition-specific inoculant, such as those from the Magniva range, is equally important to ensure optimal fermentation and feed out stability.

Magniva Platinum Crimp contains a substantial dose of heterofermentative bacteria as crimp is prone to mould growth. These bacteria help to rapidly establish a beneficial microbial population that ferments the grain efficiently, preserving its high-energy starch content and making it rumen friendly.

Inoculants should be applied to crimped grains during the crimping process. This is because as the grains are crimped, they are broken and exposed, which allows the inoculant to penetrate and work more effectively.

It is important to use an applicator that sprays the inoculant onto the grains as they pass through the crimping rollers as this ensures uniform coverage.

Using inoculants on both wholecrop silage and crimped grains enhances fermentation, reduces spoilage, and ensures high-quality feed for your livestock. Proper clamping techniques are key to maximising the benefits of inoculants.

How to clamp cereals correctly

When filling the clamp, work in thin, even layers of no more than 20 cm thick to achieve uniform compaction and minimise the risk of air pockets.

Compact each layer thoroughly to ensure there is no air trapped in the hollow, waxy stems of the crop. This is crucial to create an anaerobic environment which is needed for good fermentation.

Make sure to seal the clamp with a true oxygen barrier, such as Silostop, to prevent air getting in. By following these steps, you can reduce spoilage and ensure high-quality, well-preserved silage for your livestock.

Clamping crimped grain effectively is essential for preserving its nutritional value and ensuring high-quality feed.

Start by crimping the grains at the 'cheddar cheese' consistency, applying the inoculant during the crimping process. It’s important to ensure the grain is harvested and passes through the crimper within 24 hours to minimise spoilage.

Fill the clamp in thin, even layers, aiming for about 15-20 cm per layer. This helps avoid air pockets that can lead to spoilage.

Continuous compaction as you fill the clamp ensures that each layer is tightly packed. After filling, cover the clamp immediately with a true oxygen barrier, securing it with weights to maintain an airtight seal. This will ensure the crimped grain is well-preserved.

By following these methods for harvesting and clamping cereals and including the use of crop- and condition-specific inoculants, you can ensure high-quality feed options for your livestock.

GET YOUR COPIES

Click here to find out more about our full range of crop and condition specific inoculants.

Here to help

Contact us nowPublished Jun 11, 2024 | Updated Sep 17, 2024

Related articles

Need specific information?

Talk to an expert